Ball-column Turntable

Luoyang Xinneng Bearing Manufacturing Co., Ltd. is a high-tech enterprise specializing in R&D and manufacturing of wind power yaw pitch bearings and turntable bearings.

Category :

Slewing Bearing

Contact Us

- Product Description

- Specification

- Detailed Picture

-

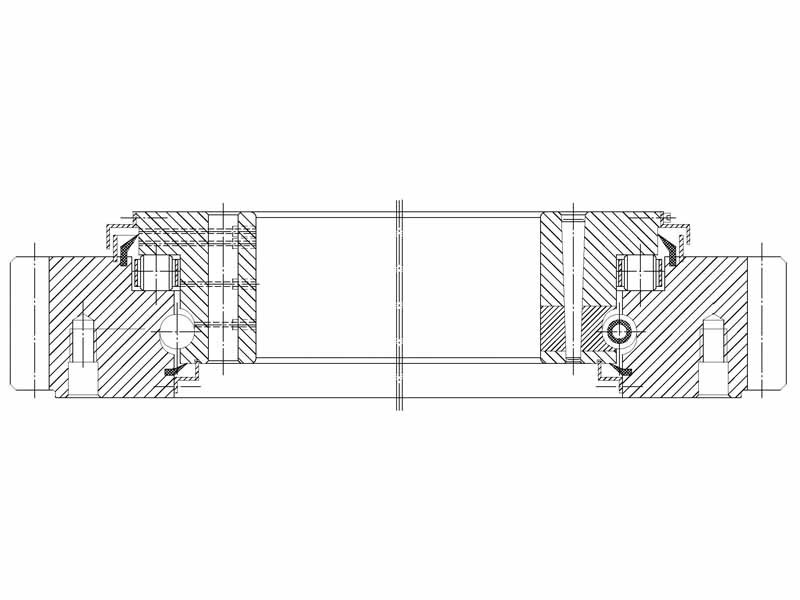

- Commodity name: Ball-column Turntable

Luoyang Xinneng Bearing Manufacturing Co., Ltd. is a high-tech enterprise specializing in R&D and manufacturing of wind power yaw pitch bearings and turntable bearings.

Luoyang Xinneng Bearing Manufacturing Co., Ltd. is a high-tech enterprise specializing in R&D and manufacturing of wind power yaw pitch bearings and turntable bearings. The current product categories can be divided into: four-point contact ball slewing bearing, double-row ball slewing bearing, crossed roller slewing bearing, three-row cylindrical roller slewing bearing, ball-column combined slewing bearing.

The ball-column combined turntable is mainly used in the bottom of the large walking stacker-reclaimer, and mainly bears the axial load and overturning moment. At present, the ball-column combined turntable bearing models produced by Xinneng Bearing are 221.40.3458.03, 221.35.4000.03, 221.35. 2500.03 and other models, due to the late start of the domestic ball-column combined slewing bearing, the product model is generally marked according to the model of the German Rothe Aid.

For more product information and technical service support, please contact Luoyang Xinneng Bearing Manufacturing Co., Ltd., Tel: 0379-6730818, E-mail: sales@nebearing.com

Key words:- Ball-column Turntable

-

Product model: 221.40.3548.03 Product structure: Ball-column slewing bearing (slewing bearing) Inner and outer ring material: 42CrMo Inner and outer ring modulation hardness: 229—269HB (can be adjusted according to customer requirements) Hardness of raceway quenching: 55—62HRC Inner diameter: 3338mm Outer diameter: 3911.6 mm Assembly height: 276 mm Inner ring mounting holes 80X φ26 Outer ring mounting holes 80X M24 Cage material: Nylon 1010 (optional steel, copper, according to working conditions) Installation method: Horizontal installation Accuracy class: P0 (can be customized according to customer requirements) Report available: Material list, final inspection report, modulation report, flaw detection report, etc. Product third-party certification ISO-9001-2015, CCS, DNV, BV, ABS, etc. Delivery time: 45—75 days Packaging: Plastic cloth + kraft paper + blue wrapping tape + wooden box (fee required) Application areas: Marine cranes, aerial work platforms, truck-mounted cranes, loaders, excavators, medical CT machines, shield machines, ladle turntables, port cranes, etc.

-