Slewing Bearing Slewing Bearing Luoyang Xinneng Bearing

Luoyang Xinneng Bearing four-point contact ball slewing bearing (slewing bearing) can bear axial load, overturning moment and radial load at the same time.

Category :

Slewing Bearing

Contact Us

- Product Description

- Specification

- Detailed Picture

-

- Commodity name: Slewing Bearing Slewing Bearing Luoyang Xinneng Bearing

Luoyang Xinneng Bearing four-point contact ball slewing bearing (slewing bearing) can bear axial load, overturning moment and radial load at the same time.

Luoyang Xinneng Bearing four-point contact ball slewing bearing (slewing bearing) can bear axial load, overturning moment and radial load at the same time. Under the combined action of axial load and overturning moment, almost all steel balls are involved in bearing the load. When subjected to pure axial load, the steel ball and the inner and outer ring raceways are in single-point contact. When the radial load exceeds a certain value, the steel ball and the inner and outer ring raceways have two points of contact respectively, at this time, the wear and friction torque will increase. In order to cope with different combinations of axial force, overturning moment and radial force generated under various working conditions, the contact angle can be adjusted accordingly.

Tel: 0379-67308188, Email: sales@nebearing.com

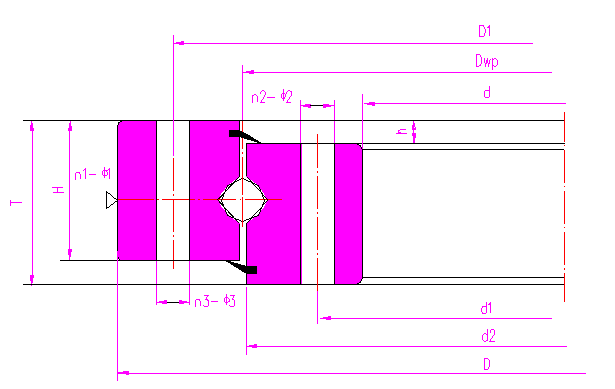

Luoyang Xinneng Bearing four-point contact ball slewing bearing (slewing bearing) is mainly composed of inner ring, outer ring, single row of steel balls, cage (or isolation block), sealing device and other parts.

Luoyang Xinneng four-point contact ball slewing bearing inner ring and outer ring have integral and split structures. The rigidity of the integral ferrule is relatively strong, and the split type is easy to adjust. The split type structure has been connected with two split rings by bolts before the product leaves the factory.

Luoyang Xinneng Bearing four-point contact ball slewing bearing (slewing bearing) usually has a cage (or spacer block), only when the load is large, the full-complement ball structure is adopted, and the full-complement ball four-point contact ball bearing has a large bearing capacity. However, the friction resistance is large, and the friction can easily cause scratches on the surface of the steel ball.

According to the installation needs, the installation holes can be designed as straight holes, countersunk holes, threaded blind holes, threaded through holes, etc.

Luoyang Xinneng Bearing four-point contact ball slewing bearing (slewing bearing) is suitable for occasions where axial load is the main, there is overturning moment and friction resistance is small. During installation, the support is required to have sufficient radial rigidity.

Key words:- Slewing Bearing

-

NumberBearing ModelDimensionsRelated SizeGear parametersdDTD1d1d2HhDwpn1n2n3Φ1Φ2Φ3dabmZxmmmm1011.30.1115.03/p59801250851202102811157510111562424M10x12222129460816002011.25.1120.12K101379118310571121709112053030M10x122M2012787010125+0.53011.40.1120.03K9981242100119810421118.59010112063636M10x1222212988010127+0.54011.40.1120.03K19981242100119810421118.59010112061818M10x1M202212988010127+0.55011.40.1124.03975127299121210351125909112454445M10x130301329.68912108+0.56011.45.1250.03K11101101337116312481001012504040M10x126M2414641001212007011.45.1250.03K11110141212813601163125210028125084040Rc1/426261473.69012120+0.58011.40.1250.03/P6110813901021336116412519012125043232M10x1M24M2414508010144-0.59011.50.1251.03109014161191352115012531107125145152M10x130301473.69812120+0.510011.30.895.03K1/P5760102095980820887851089521616M10x1M16M161096704272011011.25.900.03D792100478964836898681090022020M14x1.5M20M201048588130-0.512011.22.900.03/P579697760950842898.555590042424M10x111111006505200-0.413011.22.900.03K/P579697760950842898.555590042424M10x113.513.51006505200-0.414011.35.900.03/P4G17701020100970830898851590041616M10x118181050695209-0.515011.40.900.127781022100978822901801090063030Rc1/422221062.4808130+0.516011.40.900.037781022100978822901801090063030Rc1/422221062.4808130+0.517012.30.900.03K/P5778100978822899901090023232M10x122221072908132018012.30.900.03K2/P5778100978822899901090023232M10x1222210729081320191787/905K90590111694510567119105563030Rc1/422M2011987110118-0.1201787/905K190590111694510567119105563030M8x122M2011987110118-0.121011.20.945.03K83456985862942.5461094542020M8x118M121048468129022011.20.945.03K183456985862942.5461094542020M8x118M121048468129023011.12.960.03/P5900101040990930958.536496041616M6x1M10111026303340024011.25.974.11882.683.31015922974.6746.3974230301/85/85/81097.287410.16107-0.525011.25.1000.03/P6892110478106493610016810100042424M10x122M201152588143-0.526011.40.1000.03K87811221001078922998.59010100063636M10x1222211888010116+0.527012.40.1000.1287811221001078922998.59010100063636M10x122221188809696+0.5281788/1040K1040801220108011597010115153030M10x1M16M1613207010129+0.529E1788/1040K410408012201080113870101147303017.5M161314.17010125030E1788/1040K510408012201080113870101147303017.5M161314.17010125031011.25.1055.03K9558011169951057719105543030M10x122M2011987110118032011.25.1055.03K/P695511508011169951057719105543030M10x122M2011987010118033011.40.1064.0391512129911529751065909106443940M10x130301269.68912103+0.534D1787/10751075136512013101130121810515122043636M8x126261424908176035011.30.1455.031305901516134514567119145562424M10x122M20160071101580

NumberBearing ModelDimensionsRelated SizeGear parametersdDTD1d1d2HhDwpn1n2n3Φ1Φ2Φ3dabmZxmmmm1011.30.1115.03/p59801250851202102811157510111562424M10x12222129460816002011.25.1120.12K101379118310571121709112053030M10x122M2012787010125+0.53011.40.1120.03K9981242100119810421118.59010112063636M10x1222212988010127+0.54011.40.1120.03K19981242100119810421118.59010112061818M10x1M202212988010127+0.55011.40.1124.03975127299121210351125909112454445M10x130301329.68912108+0.56011.45.1250.03K11101101337116312481001012504040M10x126M2414641001212007011.45.1250.03K11110141212813601163125210028125084040Rc1/426261473.69012120+0.58011.40.1250.03/P6110813901021336116412519012125043232M10x1M24M2414508010144-0.59011.50.1251.03109014161191352115012531107125145152M10x130301473.69812120+0.510011.30.895.03K1/P5760102095980820887851089521616M10x1M16M161096704272011011.25.900.03D792100478964836898681090022020M14x1.5M20M201048588130-0.512011.22.900.03/P579697760950842898.555590042424M10x111111006505200-0.413011.22.900.03K/P579697760950842898.555590042424M10x113.513.51006505200-0.414011.35.900.03/P4G17701020100970830898851590041616M10x118181050695209-0.515011.40.900.127781022100978822901801090063030Rc1/422221062.4808130+0.516011.40.900.037781022100978822901801090063030Rc1/422221062.4808130+0.517012.30.900.03K/P5778100978822899901090023232M10x122221072908132018012.30.900.03K2/P5778100978822899901090023232M10x1222210729081320191787/905K90590111694510567119105563030Rc1/422M2011987110118-0.1201787/905K190590111694510567119105563030M8x122M2011987110118-0.121011.20.945.03K83456985862942.5461094542020M8x118M121048468129022011.20.945.03K183456985862942.5461094542020M8x118M121048468129023011.12.960.03/P5900101040990930958.536496041616M6x1M10111026303340024011.25.974.11882.683.31015922974.6746.3974230301/85/85/81097.287410.16107-0.525011.25.1000.03/P6892110478106493610016810100042424M10x122M201152588143-0.526011.40.1000.03K87811221001078922998.59010100063636M10x1222211888010116+0.527012.40.1000.1287811221001078922998.59010100063636M10x122221188809696+0.5281788/1040K1040801220108011597010115153030M10x1M16M1613207010129+0.529E1788/1040K410408012201080113870101147303017.5M161314.17010125030E1788/1040K510408012201080113870101147303017.5M161314.17010125031011.25.1055.03K9558011169951057719105543030M10x122M2011987110118032011.25.1055.03K/P695511508011169951057719105543030M10x122M2011987010118033011.40.1064.0391512129911529751065909106443940M10x130301269.68912103+0.534D1787/10751075136512013101130121810515122043636M8x126261424908176035011.30.1455.031305901516134514567119145562424M10x122M20160071101580Product model: 011.25.1120.03K Product structure: Four-point contact ball external tooth turntable (slewing bearing) Inner and outer ring material: 42CrMo Inner and outer ring modulation hardness: 229—269HB (can be adjusted according to customer requirements) Hardness of raceway quenching: 55—62HRC Inner diameter: 1013mm Outer diameter: 1278 mm Assembly height: 79mm Inner ring mounting holes 30X M20 Outer ring mounting holes 30X M20 Cage Material: Nylon 1010 (optional steel or copper, according to working conditions) Installation method: Horizontal installation Accuracy class: P0 (can be customized according to customer requirements) Report available: Material list, final inspection report, modulation report, flaw detection report, etc. Product third-party certification ISO-9001-2015, CCS, DNV, BV, ABS, etc. Delivery time: 45—75 days Packaging: Plastic cloth + kraft paper + blue wrapping tape + wooden box (fee required) Application areas: Marine cranes, aerial work platforms, truck-mounted cranes, loaders, excavators, medical CT machines, shield machines, ladle turntables, port cranes, etc.

-