Angular Contact Ball Bearing

Angular contact ball bearings, also known as angular contact radial thrust ball bearings, are more suitable for occasions that bear radial and axial loads at the same time, and can also be used for occasions that only bear axial loads. The magnitude of the axial load varies with the contact angle, and the larger the contact angle, the greater the axial load.

Category :

Universal Bearing

Contact Us

- Product Description

- Specification

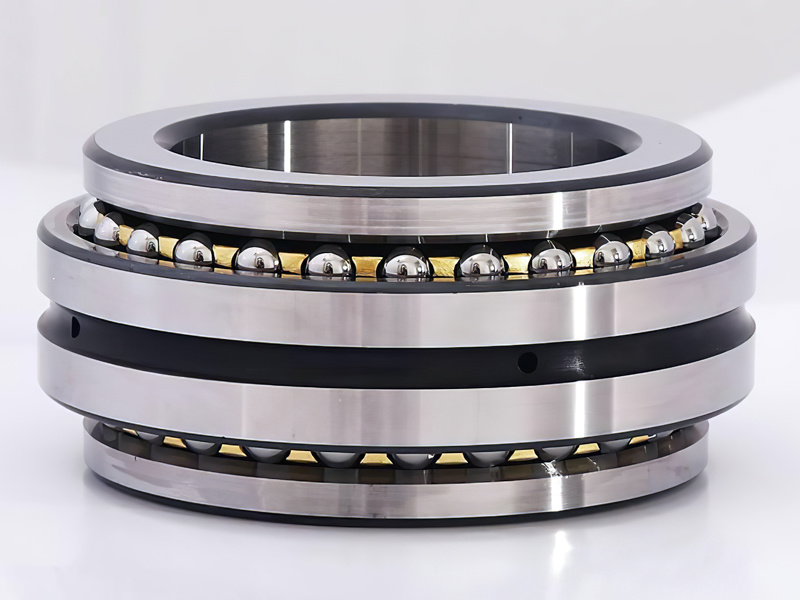

- Detailed Picture

-

- Commodity name: Angular Contact Ball Bearing

Angular contact ball bearings, also known as angular contact radial thrust ball bearings, are more suitable for occasions that bear radial and axial loads at the same time, and can also be used for occasions that only bear axial loads. The magnitude of the axial load varies with the contact angle, and the larger the contact angle, the greater the axial load.

Angular contact ball bearings, also known as angular contact radial thrust ball bearings, are more suitable for occasions that bear radial and axial loads at the same time, and can also be used for occasions that only bear axial loads. The magnitude of the axial load varies with the contact angle, and the larger the contact angle, the greater the axial load.

Angular contact ball bearings can be divided into B, C, AC, three types of contact angles according to the size of the contact angle, the B contact angle is 40 degrees, the C contact angle is 15 degrees, and the AC contact angle is 25 degrees.

Angular contact ball bearings are divided into single row angular contact ball bearings and double row angular contact ball bearings according to the number of rolling elements.

The cages of single row angular contact ball bearings have different structural types such as steel stamping cages, glass fiber reinforced polynylon 66 and car-made brass solid cages. When angular contact ball bearings are used as high-speed spindle bearings, cages made of phenolic layered pressure pipes are generally used. Different cage structures are represented by different codes, as described below.

Double row angular contact ball bearings can withstand larger radial loads and combined radial and axial loads and moment loads, limiting the axial displacement of both sides of the shaft. The inclination between the inner and outer rings of the double row angular contact ball bearing is limited in the components that are mainly used to limit the bidirectional axial displacement of the shaft and the housing. forces and moments on the bearing, and the maximum allowable inclination angle should ensure that excessive additional stress is not generated in the bearing. If there is an inclination angle between the inner and outer rings of the bearing, the service life of the bearing will be affected, and at the same time, the running accuracy of the bearing will decrease and the running noise will increase. Double row angular contact ball bearings generally use nylon cages or brass solid cages. When installing the double row angular contact ball bearing, it should be noted that although the bearing can bear bidirectional axial load, if there is a gap for the ball on one side, care should be taken not to let the main axial load pass through the groove on the side with the gap. When the bearing is used, care should be taken to make the side raceway without the ball-loading notch bear the main load.

Back-to-back configuration, the rear code is DB (such as 70000/DB), and the load lines of the back-to-back paired bearings are separated from the bearing shaft. Axial loads acting in both directions can be supported, but loads in each direction can only be supported by one bearing. Back-to-back mounted bearings provide a relatively rigid bearing arrangement and can withstand overturning moments. Face-to-face configuration, the rear code is DF (such as 70000/DF), and the load lines of the face-to-face paired bearings converge to the bearing shaft. Axial loads acting in both directions can be supported, but loads in each direction can only be supported by one bearing. This configuration is not as rigid as a back-to-back pair, and it is less suited to withstand overturning moments. The rigidity of this configuration and the ability to bear the overturning moment are not as good as that of the DB configuration, and the bearing can bear bidirectional axial loads; in the series configuration, the rear code is DT (such as 70000/DT), in the series configuration, the load line is parallel, and the radial and The axial load is evenly shared by the bearings. However, bearing sets can only withstand axial loads acting in one direction. If the axial load is acting in the opposite direction, or if there is a compound load, a third bearing that is adjusted relative to the tandem paired bearing must be added. This configuration also allows three or more bearings to be connected in series at the same support, but can only bear axial loads in one direction. Usually, in order to balance and limit the axial displacement of the shaft, a bearing that can bear the axial load in the other direction needs to be installed at the other support.

Application field:

Single row angular contact ball bearings: machine tool spindles, high frequency motors, gas turbines, centrifugal separators, front wheels of small cars, differential pinion shafts, booster pumps, drilling platforms, food machinery, indexing heads, repair welding machines, Low-noise cooling towers, electromechanical equipment, painting equipment, machine tool slot plates, arc welding machines Double row angular contact ball bearings: oil pumps, Roots blowers, air compressors, various transmissions, fuel injection pumps, printing machinery, planetary deceleration Machine, extraction equipment, cycloid reducer, food packaging machinery, electric welding machine, electric soldering iron, square box, gravity spray gun, wire stripping machine, half shaft, inspection and analysis equipment, fine chemical machinery.

Luoyang Xinneng Bearing Manufacturing Co., Ltd. specializes in the production of large angular contact ball bearings, such as: 71984, 719/630AC, and other models.

For more product information and technical support, please contact the Marketing Department of Luoyang Xinneng Bearing Manufacturing Co., Ltd., Tel: 0379-67308188, E-mail: sales@nebearing.com

Key words:- Angular Contact Ball Bearing

-